My vermiculture adventure started in November 2018 a couple months after I returned to Texas from my eco-road trip . Having spent the previous seven months up at an intentional community in Oregon, I wanted to continue my greener living with something easy I could do.

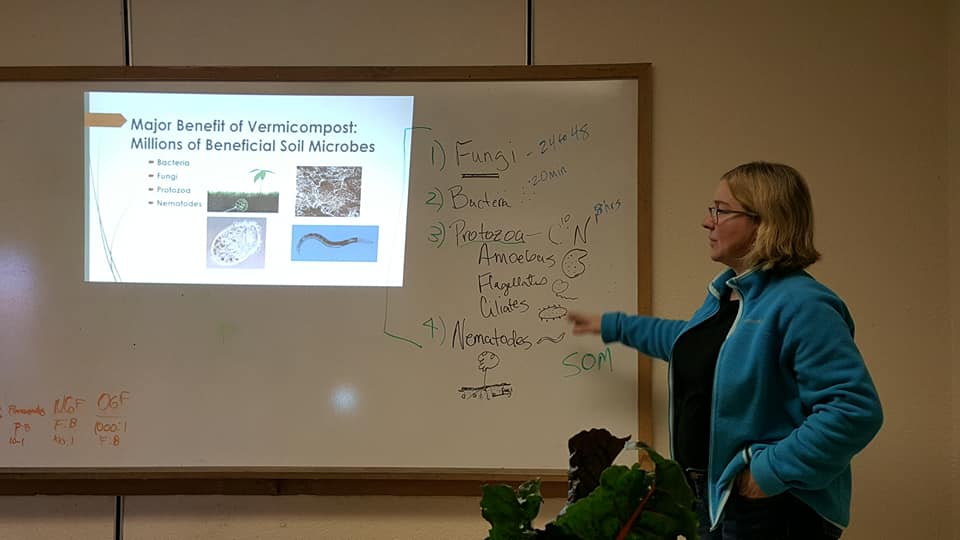

I saw a DIY worm bin class advertised online with the Texas Worm Ranch, and figured it might be interesting. Little did I know how big these little guys would become in my life after I got my first worm bin going!

Texas Worm Ranch

Texas Worm Ranch sells their worm castings [poop] to organic gardeners as a nutrient and microbe rich soil amendment, and makes a liquid, worm casting yard and garden treatment called Worm Wine ™. (Worms)

– Green Source DFW

As part of the DIY worm bin class, attendees were also given a tour of the facilities and given an overview of the operations. The inputs of food and bedding for the worms came from established waste streams. So by pulling from waste streams, there is little to no cost for the bulk of what worms need. The facilities also used color coded flags to indicate stages and needs for each bed, like “needs watering” or “harvest soon, don’t feed.”

Our tour guide walked us through the worm bin maintenance steps before we received our own bins. He also pointed out the eggs in the soil mix, and gave us tips for moisture control with adding or removing newspaper strips.

Heather Rinaldi, self-described “worm rancher”

If you called me Mom, wife, entrepreneur, gardener, health promoter, food enthusiast, mom taxi, athletic coordinator, head cheerleader, nature lover, environmental activist, soil remediator, idealist, educator, biologist, researcher and aspiring author you would be correct. If you added accountant, janitor, web administrator, marketing pro, poop shoveler, waste management professional or recycler, you would also cover a few of the hats I wear.

She’s the sole proprietor of Texas Worm Ranch, a 16,000-sq ft facility in Dallas, TX that produces organic vegetables and processes over 5000 lbs of waste per week. She has a diverse and knowledgeable customer base with revenues growing around 15% per year without an advertising budget.

– Urban Worm Interview Series: Heather Rinaldi, Urban Worm Company

Heather is definitely a woman who wears many hats! Her knowledge and experience show when she talks about vermiculture. And she has the scientific understanding to explain the microbiologic processes to regular folks too. Heather’s business model and operations are very impressive to say the least, but what’s more impressive is how well she shares her passion, the field of vermiculture, with others!

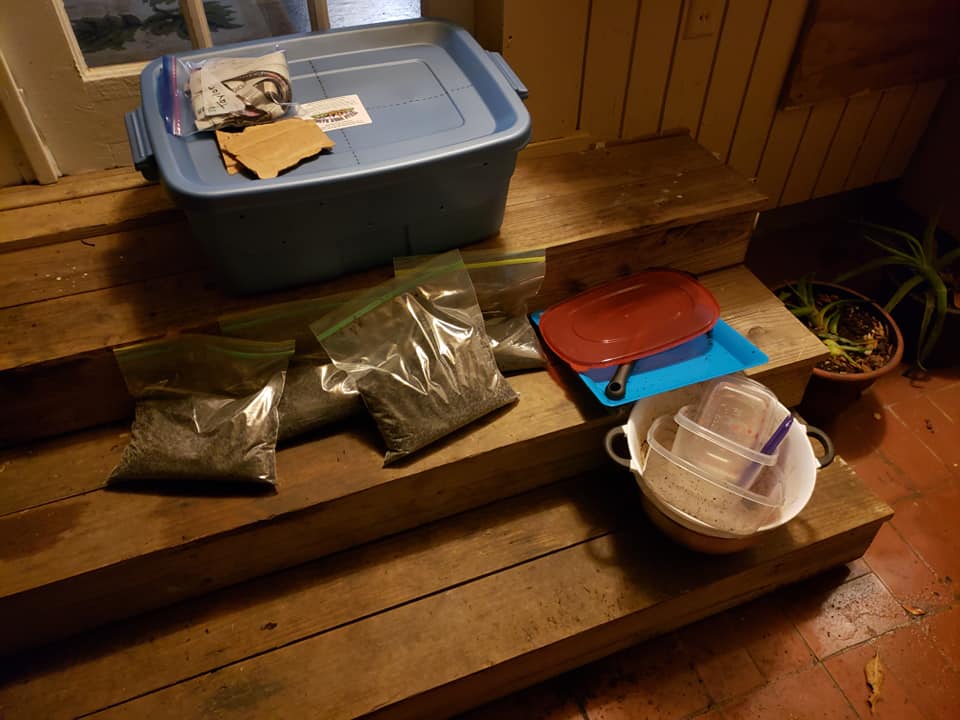

My First Worm Bin

I started off with one worm bin. This was easy for me to manage as a renter who had the occasional food scraps. The worm bin was comparable to a fish tank mixed with an ant farm, being self-contained, quiet, and not smelly at all!

My first harvest took several hours and was back-breaking manual work. Like sifting for gold. It wasn’t something I looked forward to doing often. Which was a benefit of the worm bins only being harvested after 60-90 days, depending on how much one feeds them.

Hand Harvest of Castings

I used a spagetthi strainer and kitty litter scoop a few more times for harvesting until I switched over to the light sifting method.

I pointed a lamp at the castings which caused the photophobic worms to burry deeper into clumps. Then I brushed off the top layers of pure castings until I got to the worms all clumped together.

The light harvesting method also took a while, but it was much easier than the manual shaker sifting I was doing by hand previously.

One Bin Grows to Four Bins

After I moved to Austin, I decided to expand my worm operations to four bins! I took the worms of my first bin and quartered the population counts so they evenly divided into all the bins. I filled each bin with fresh compost, a handful of worms, and a few scoops of veggies for food before I added a newspaper bedding layer. Since these bins are designed for storage, their sizes where also perfect to stack on shelving towers to conserve space!

Four Bins Grow into Eight Bins

A few cycles into my four worm bin operation, I thought to myself, “I could easily double my bins with how many worms I have in each one…” Which was the thought to lead me from four bins and doubling to an eight bin operation. I added a second tower for my new stackable bins and doubled up my feedings – requiring me to actually purchase food for them since I did not produce enough food waste.

Eight Bins Grow into Twelve Bins

I thought to myself again, “I could easily add more bins with how many worms I have…” Maybe I could try and make enough castings for my family, or potentially to sell!

I responsibly added only four more bins to make twelve, as sixteen might be too much to handle until I had a plan for my castings.

My thoughts were to have enough bins on staggered cycles to always have fresh product on hand throughout the year. While the castings are seasonal products, casting-based teas for plants are year-round products.

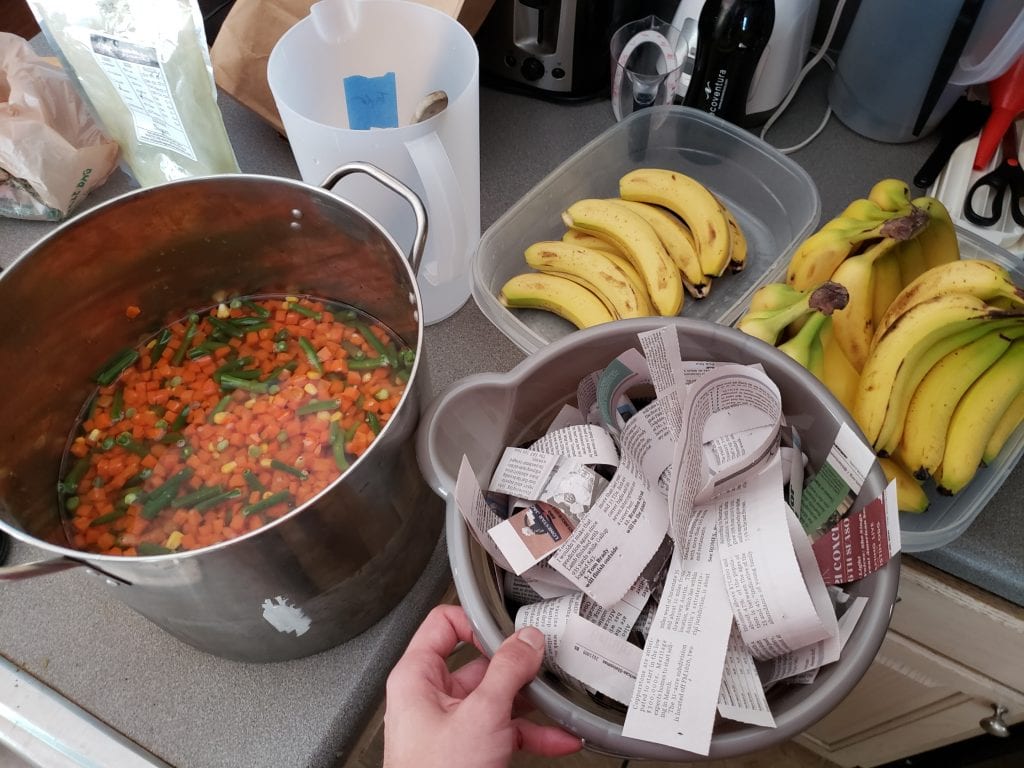

Feeding More and More Worms

Initially with my first worm bin, I made more than enough food waste for my single worm bin. However as my operation expanded, so did their need for more food. I’ve wound up buying food in bulk to supplement the food waste I produce. This mainly includes bunches of bananas and frozen bags of chopped mixed veggies. These purchases supplement the food waste my roommates and I produce, which is primarily apple cores and expired salad mixes.

I give them a well-balanced diet to enrich their castings and give them some different flavors to enjoy! The worms can also eat the newspaper if I don’t regularly feed them with my schedule.

Worm Sifter Creation

I eventually built a worm casting sifter, or a panning trommel, to help better separate my worms from my castings. I found a worm casting sifter DIY video online and recreated it. Overall, I would recommend a different style and have it mechanically powered instead of manual. But it works for my needs and slightly helps with the sifting process.

Learn how I built this worm casting sifter.

Check out my other personal projects to see what I’ve created.

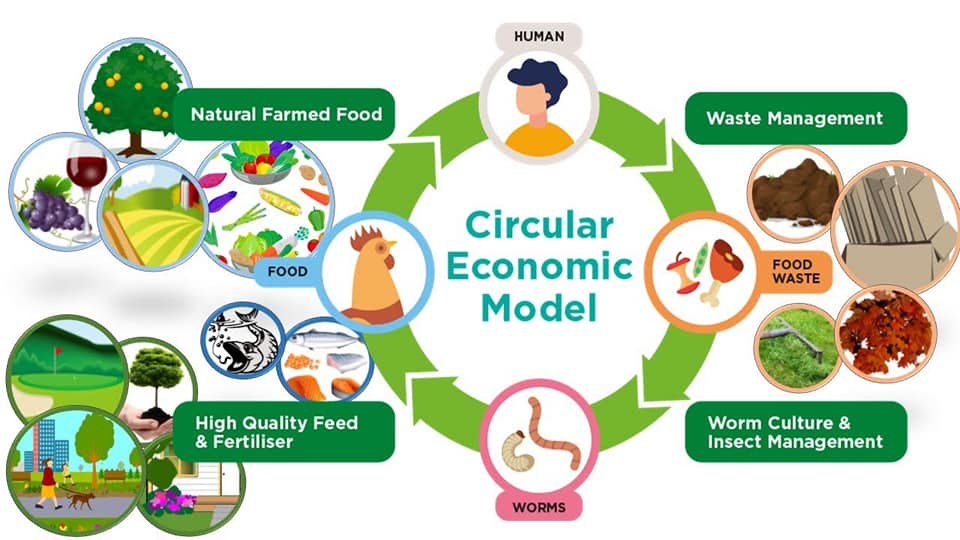

The [RE]verse Pitch Competition

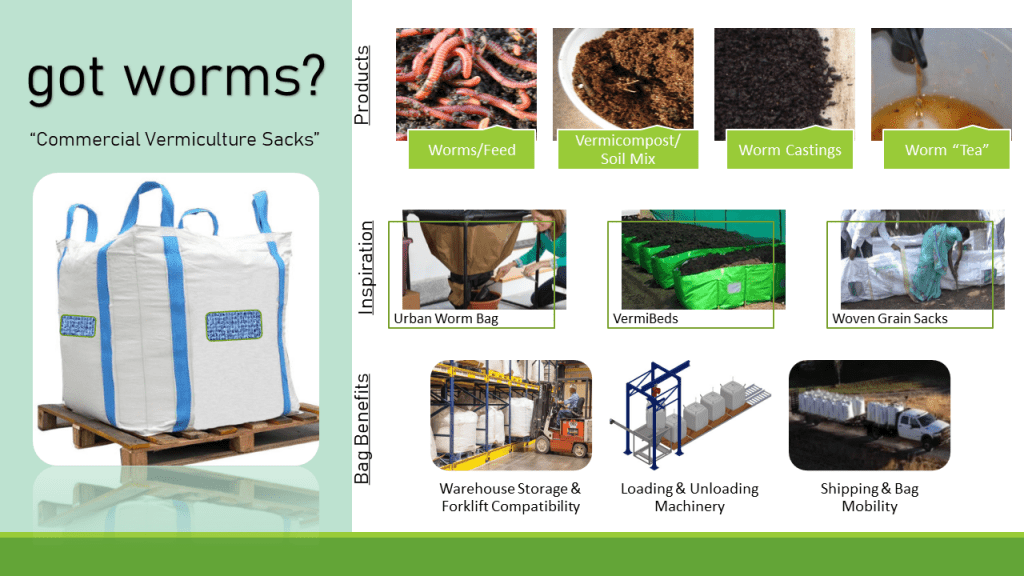

I decided to participate in the [RE]verse Pitch Competition through the city of Austin. It’s an entrepreneurial competition like Shark Tank, only the difference is that materials are pitched in reverse to the entrepreneurs. I created vermicomposting bags made from Austin Eastcider’s excess sugar Supersacks.

While I wasn’t chosen as a finalist, I still have a business plan and idea I can implement. It also opened me up to thinking about my worm operation differently. I also got plugged in with some likeminded people in the local circular economy movement.

Learn more about my attempt at the [RE]verse Pitch Competition.